Spark Gap Location and Design

For the purpose of a perfect use of the fuel energy and in order to ensure that the harmful exhaust gas emission does not exceed a minimum level, it is necessary to optimize the spark plug construction with regard to the requirements of particular engines.

The following parameters will influence the quality of the ignited air/fuel mixture in the combustion area:

- location of spark gap in the combustion chamber

- change in the electrode gap in course of the spark plug replacement interval.

- change in properties in the electrode material in course of the spark plug replacement interval

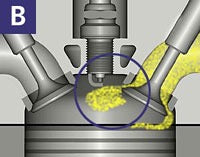

- free access of the flame face in its initial phase of propagation

- possibility of discharge location selection according to the instantaneous concentration of fuel molecules in the air/fuel mixture in the immediate surroundings of the spark gap area

Different engines require different spark plug arrangement and its location in the combustion chamber. In order to achieve longer lifetimes of spark plugs required by the engine producers, there are used multiple spark plugs and precious materials (such as platinum, silver, tungsten).

By means of shifting the insulator tip suitably out, i.e. into the combustion chamber of the engine, better access and ignition of air fuel mixture is achieved.